Aircraft on ground (AoG) incidents are every airline’s worst nightmare. They are expensive, inconvenient for passengers and undermine trust. However, in many African markets, the root cause of unnecessary grounding is not the mechanics, but rather the delay in receiving the right parts quickly and consistently.

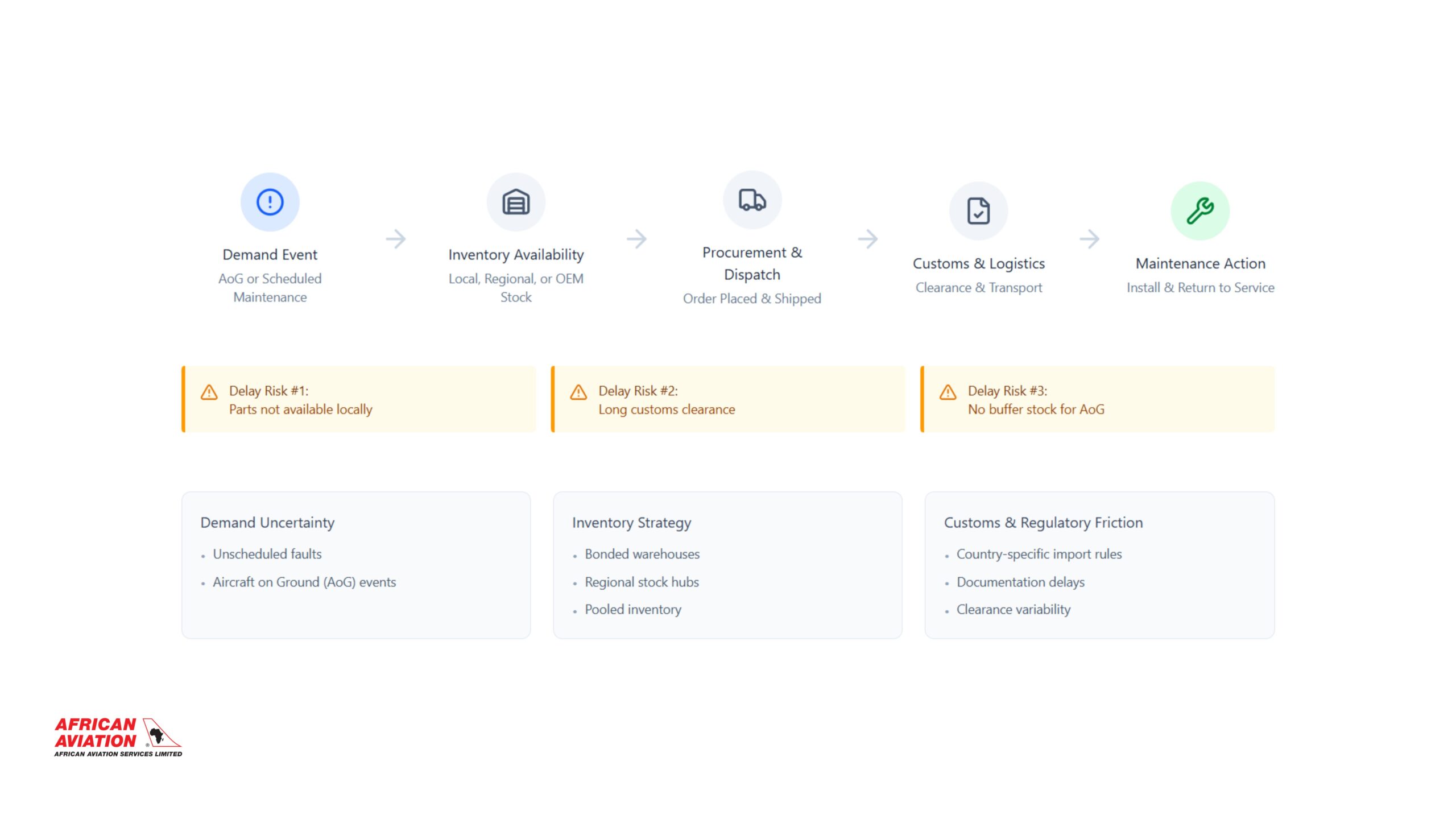

One of the most important performance metrics in aviation operations is lead times, which are the total time from identifying a part need to installing it. When lead times are extended, particularly during AoG events, airlines lose revenue, schedules deteriorate and trust erodes.

This is not just a theory. According to industry data, global supply chain bottlenecks and increased parts lead times are putting significant strain on airlines’ maintenance operations. According to IATA’s most recent supply chain data, ongoing bottlenecks are contributing to increased costs, longer aircraft downtime, and limited operational flexibility across the industry.

Below, we unpack why lead times are important, what causes delays in Africa and practical strategies that airlines and MROs can use to improve response times and aircraft availability.

Why Lead Time Is Important and What “Good” Looks Like

In basic terms, lead time is the time between when a maintenance need is identified and when the aircraft is returned to service. The shorter the clock, the more reliable and profitable.

According to industry data, supply chain disruptions, such as geopolitical tensions and global parts shortages, are now the leading cause of aviation delays and increased operational costs. According to one source, disruptions caused more than $11 billion in additional industry costs in 2025 alone, owing primarily to extended parts delays and spare inventory costs.

But what makes lead times worse in Africa?

Across Africa, airlines and MRO partners face several compounding challenges:

- Complex Customs & Logistics: Each country has its own import regulations and procedures. Without pre-cleared warehouses, parts can sit at borders for days even if the flight that requires them is grounded. Officials, paperwork and regulatory checks all contribute to increased wait time.

- Global Supply Chain: Aircraft spare parts are not manufactured locally. Most components are sourced globally and international supply chains have been strained following the pandemic, resulting in longer procurement cycles and unpredictable delivery dates.

- Lack of Local Inventory: Most airlines keep their inventory near majot global hubs. In Africa, parts frequently have to travel long distances, resulting in longer lead times and higher costs.

Technology Helps, But It Is Not Enough

New digital solutions such as procurement platforms and shared inventory systems are improving transparency and communication among airlines, suppliers and MRO facilities, sometimes significantly.

For example:

Neutral buying platforms such as Aeroxchange, offer digital workflows that reduce manual communication and speed up sourcing processes.

Industry asset management platforms allow airlines to see where parts are and source them more quickly.

However, technology alone cannot overcome structural friction unless it is combined with local inventory and regulatory strategy. That is because:

- Visibility without availability simply exposes the problem faster.

- Faster digital ordering still results in slow customs lanes unless parts are pre-cleared or staged.

Why Bonded Warehouses and Strategic Inventory Matter

One reason parts sit at customs is that they do not have pre-approved status. Airlines and MROs can significantly reduce import wait times by establishing bonded inventory facilities, which are pre-cleared storage facilities located inside or near major airports.

Benefits include:

- Instant dispatch to maintenance facilities

- Avoiding multiple customs clearances for high-turn parts.

- Faster AoG resolution

These benefits are especially important in Africa, where customs complexity and logistics latency are significantly higher than in well-serviced global hubs.

What does A Practical Playbook Look Like?

Improving lead times necessitates a combination of technology, infrastructure and supply chain strategy.

Predictive Part Placement: Use historical AoG and repair data to forecast high-demand parts and place them in regional bonded warehouses.

Digital Connectivity: Connect suppliers, MRO shops, and airline planners via shared platforms to reduce sourcing delays and improve response coordination.

Regulatory Navigation: Collaborate with local authorities to improve customs handling for aviation parts, ideally through agreements that recognise bonded stock or expedited clearance for priority aviation imports.

Alternative sourcing: Investigate secondary markets such as Used Serviceable Materials (USM), which are increasingly in demand and can relieve pressure on new OEM parts supply.

What Does This All Mean?

The opportunity for African airlines and MRO facilities is clear: reducing lead times requires not only working faster, but also working smarter.

By combining local inventory readiness with digital procurement platforms and strategic customs and logistics planning, operators can reduce AoG durations, lower costs and enhance operational reliability.

The future belongs to those who recognise supply-chain challenges and take proactive steps to address them.

Sources

https://www.iata.org/en/pressroom/2025-releases/2025-10-13-01

https://www.iata.org/en/programs/ops-infra/techops/aviation-supply-chain

https://www.researchgate.net/figure/The-aircraft-supply-chain-structure_fig1_323355463

https://airlines.iata.org/2025/03/30/solving-spare-parts-challenge

https://play.google.com/store/books/details?id=rXizEAAAQBAJ&source=gbs_api